If you would like to print up one of these handy tool caddies for yourself, you can find my design on Watertight. The longevity of this print is 15 hours and 27 minutes.

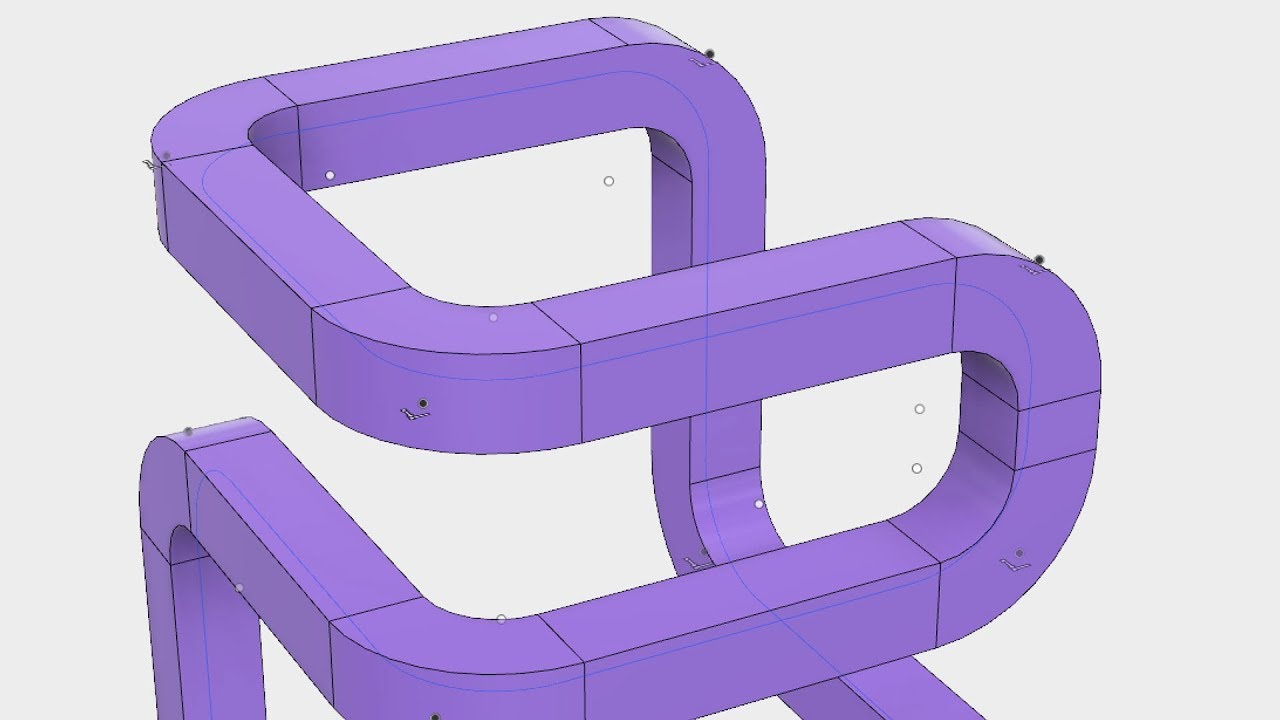

For bed adhesion, I applied one coat of Wolfbite for ABS prior to heating the bed and my part stuck firmly to the glass. ABS filament in Natural was my material of choice because of its impact resistance, strength and stiffness. I used Cura as my printing slicing software and ABS standard settings (hot end temperature at around 235-255☌ and bed temperature between 110-130☌). How to 3D print an Airwolf 3D Tool Caddyįor this design, I decided to use the AW3D AXIOM 3D printer. I wanted everything to have a place, so I made sure to have a compartment for all the important tools and accessories needed to run an Airwolf 3D printer. I thought, how cool would it be to have something similar to a regular toolbox, but for all my Airwolf tools that I use on a daily basis? The idea for my Tool Caddy design came from always misplacing my tools. I still have a lot to learn, but seeing how well this project turned out is definitely great motivation to keep on learning. It took me about three weeks to learn the basics of Fusion 360 and perfect my design. It is definitely more sophisticated than some other types of software, but that makes me even more excited about what I’ll be able to create. I became intrigued when I saw all the incredible possibilities that 3D printing offers. Before working here, I didn’t know anything about 3D printing or design. I became an Airwolf 3D employee in April of 2015.

0 kommentar(er)

0 kommentar(er)